S0005850

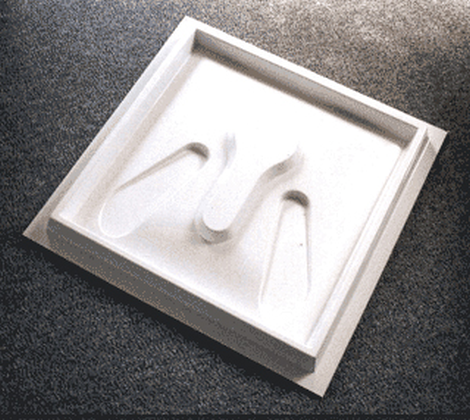

Mould,plastic,for concrete latrine slab

Polymeric mould for concrete latrine slabs; packed in boxes of 10 or 50 each

Indicative Price 36.00 USD

General Description:

Polymeric mould for concrete latrine slab

Technical Specifications:

Plastic form made of high quality polymers with very smooth finish. The material of the form is UV protected; impact resistant; thickness of the mould material is 4 mm and can stand rough handling under field conditions.

The finished latrine slab will have horizontal dimensions of (60 x 60 cm) and thickness of around 8 cm. The produced slab has two raised foot rests and a drop-hole with dimensions well selected to make it safe for use by small children. The finished surfaces have slopes towards the drop hole for easy cleaning.

The drop-hole form on the slab can be turned on the other side to cast the drop-hole cover.

Packaging and labelling:

The forms are supplied in boxes of 10 or 50 on a pallet.

Weight/Volume/Dimensions:

Estimated weight: 2 kg

Estimated volume: 44 cdm

Instructions for use:

The form is used to cast concrete slabs or platforms for any kind of latrines. Before casting concrete, a layer of oil should be applied to the mould before casting concrete to facilitate separating the concrete slab from the form after the concrete has hardened.

It is recommended to cast the concrete in two layers, the first one being thin (1-2 cm) and very fluid in order to ensure the smooth finish; after casting this layer, all the air bubbles must be removed by hitting the mould gently with a piece of wood. The reinforcement is then added (these are mainly for transportation purposes) and the second stiff layer of concrete cast. The mould should then be left in a humid atmosphere for the concrete to harden and allow for the removal of the slab form the mould.

The form should be cleaned immediately after removing the slab to be ready for the next casting.

The form can be turned on the other side to cast the drop-hole lid in the same way.

Related Products